News & Blogs

In this blog, we touch on diverse topics about Japanese food cultures, practices together with the culinary secret, TREHA®, and its important role in the Japanese food industry. We hope our blog helps you obtain in-depth knowledge of the secrets and science behind Japanese cuisine, shared from our kitchen, to yours.

We interviewed Dr. Suzuki, a specialized professor at Tokyo University of Marine Science and Technology in August, 2022. He has conducted research about food freezing technologies and glass transition behavior of many substances. He talked about what is “freezing” from scientific point of view, and key factors of keeping frozen foods’ quality. Main topics of this time are about mechanisms of quality loss in frozen foods, and best way to thaw frozen food while keeping quality.

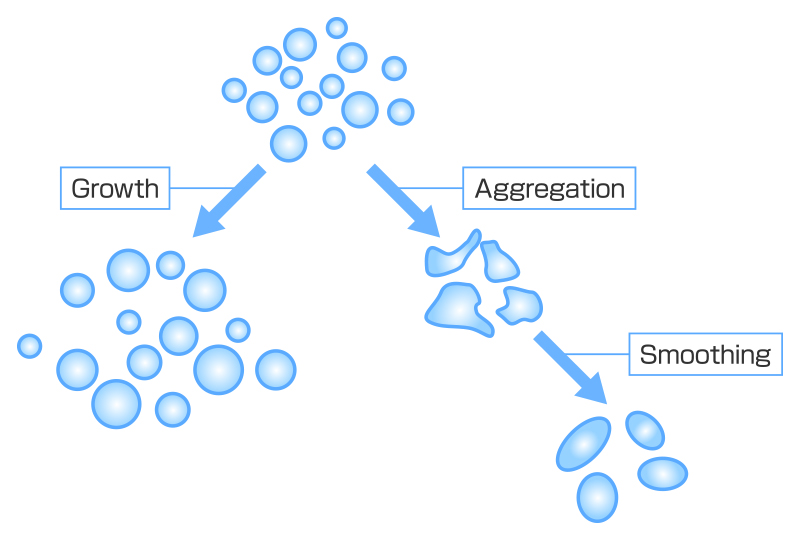

The universe in ice cream – aggregation and growth of ice crystals, movement of moisture

Team TREHA®: Whenever hearing the word “frozen food”, I always think of frozen desserts, like ice cream. Are there any techniques behind ice cream manufacturing such as ingredient formulation and processing methods?

Prof. Suzuki: Mouthfeel of ice cream is determined by ice crystal size inside. The smaller the ice crystals, the smoother the texture. Poor storage conditions for ice cream, such as -5℃/23℉, makes the ice crystals grow to a visible size (around 1mm) and results in a coarse mouthfeel. The best way to maintain a smooth texture is to keep storage temperatures low enough (-20℃/-4℉); however, there are limitations in logistics and in freezing conditions of a household freezer. The temperature fluctuates when the freezer’s door is opened. Thus, the manufacturers of ice cream have tried to improve formulation of ice cream to maintain small ice crystals. One of the ingredients to inhibit ice crystal growth is trehalose. Trehalose inhibits ice crystal growth in ice cream.

Team TREHA®: It’s nice to know that the manufacturers make efforts to prevent ice crystal growth even in poor storage conditions.

Prof. Suzuki: You may think how ice crystal growth happens is obvious; however, the mechanism behind the phenomenon is not always revealed. According to the earlier microscopic research, ice crystals found in ice cream are a mixture in terms of the crystal size, from micron-size to mm-size. Moisture moves from small crystals to large crystals, and ice crystals grow as time passes. As a result, large crystals become sizable and small crystals are vanished - just like stardust in the universe. Water molecules move just like spaceships travel through the planets; it does not move directly from small ice crystals to large ice crystals, it is more likely wandering among substances such as sugar, fat and air bubbles. Ice crystal growth is inhibited by trehalose, because trehalose catches moisture among ice crystals and inhibits aggregation.

The reason why frozen lettuce cannot be reconstituted.

Team TREHA®: Many people say that it is difficult to keep fresh vegetables under frozen storage without quality loss. What do you think about it?

Prof. Suzuki: I think “difficulty” refers to the expectation from consumers. Although expectation varies among food items, consumers usually expect crispy texture for fresh salad. Texture is the most vulnerable component of frozen food. Texture loss of frozen vegetables is caused by cell structure of the vegetables changing. Although cell membranes in all foods are destroyed when frozen, meat tends to maintain its texture because the cell is filled with muscle fibers. Muscle fibers maintain the elasticity of meat even after freeze-thaw. On the other hand, fresh vegetables are composed of plenty of moisture. Cells shrink when cell membranes are destroyed, because they are full of moisture and supported by hydraulic pressure. Beans and potatoes are relatively stable in quality even after freeze-thaw, because they have starch in cells, which helps contribute to maintaining the texture.

Team TREHA®: I see. Restoration of texture would be both the key, and the difficulty.

Prof. Suzuki: Yes it is. Keeping the original texture after freezing is very difficult especially for vegetables and fruits; for example, no one has been successful in freezing fresh lettuce without losing texture. However, in terms of nutrition and color, we have already achieved reasonable quality; so we can use frozen lettuce for cooking, such as in soups and fried rice.

Drying out in plastic packages?! Tricks and traps of frozen storage and how to maintain quality.

Team TREHA®: Frozen foods, especially homemade ones tend to have off-notes and discoloration when time passes. Could you tell me why that happens, please?

Prof. Suzuki: Drying out during frozen storage, in many cases. It is called “freezer burn”, sublimation of the moisture in foods. Moisture covers fats and proteins contained in foods. If foods are dried, fats and proteins are exposed and oxidized by enzymes. Freezer burn is caused by drying. You may have experienced frozen noodles that become whitish and hard to bite, even after reheating – this is due to moisture loss during freezing, which causes aggregation of starch and protein molecules that cannot be restored by heating.

Team TREHA®: Why do foods experience drying during frozen storage?

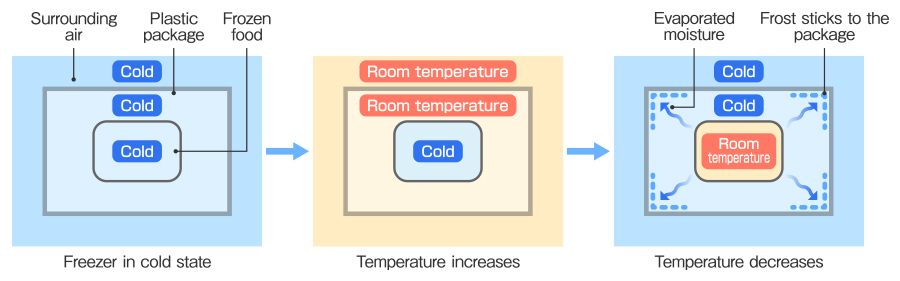

Prof. Suzuki: Unpackaged foods become dry during frozen storage because humidity in a freezer is low. A freezer has a fan with a heat exchanger, and chills the inside of the freezer by circulating air through the heat exchanger. Humidity in the air is condensed and frozen when passing through the fan. The air loses moisture and keeps circulating in the freezer. So that, inside of the freezer becomes very dry, and foods lose moisture. On the other hand, packaged foods are not exposed dry, cold air in freezer; however, even packaged food loses its moisture.

Team TREHA®: Why does packaged food lose its moisture in the freezer?

Prof. Suzuki: Packaged foods become dry due to temperature fluctuations. Temperature increases when we open the door of the freezer. When the freezer detects temperature increase, it starts chilling the air inside of the freezer. It causes a temperature difference between the food and surrounding air in the package; moisture is evaporated from food with relatively higher temperature and sticks to the package during chilling. Therefore, we can see damaged frozen foods with plenty of frost inside of the package. Moisture cannot enter back into the food once it’s evaporated, so foods continually loses moisture in a freezer.

Cited by Frozen Lab’s website, supervised by prof. Suzuki

Team TREHA®: Could we prevent the drying of frozen foods in a freezer?

Prof. Suzuki: There are two ways to maintain quality; one is to minimize temperature fluctuation of the foods. Covering food with heat-insulating materials or layered plastic wraps, or stuffing the freezer fully with frozen foods may help to keep the temperature of food. The second is lowering the temperature of the freezer as much as we can. We would be able to decrease moisture evaporation of foods by lowering freezer’s temperature to -40℃/-40℉. However, this is difficult in the real world, because household freezers are designed for -18℃/-0.4℉ and difficult to decrease the temperature lower than that; even if it were possible, it would consume excessive electricity.

Team TREHA®: We understand storage conditions are very important to keep frozen foods’ quality.

Prof. Suzuki: As I mentioned earlier, people tend to think blast freezing is the best way to keep frozen foods’ quality; however, it is not as critical as we previously expected. My study revealed that around 70% of frozen damage is caused by poor storage conditions.

Tips for defrosting while keeping quality – highlighting foods’ goodness by inhibiting enzymatic activities.

Team TREHA®: Could you give us tips for thawing frozen foods?

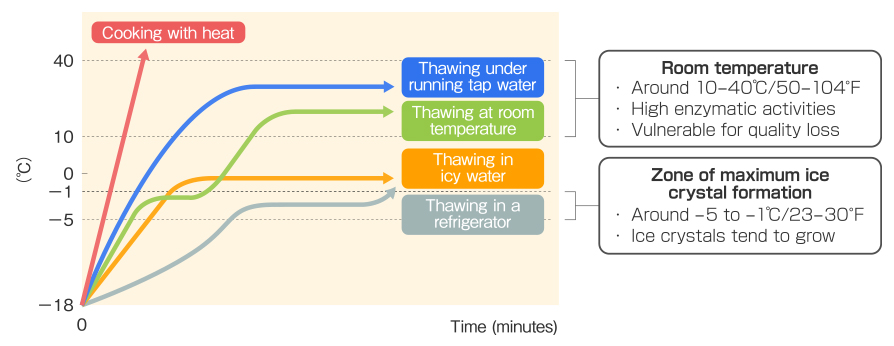

Prof. Suzuki: You’d be better to take the suitable way for thawing each food material. I’d like to take frozen tuna as an example. How can we enjoy a tuna filet, which is frozen on a fishing boat in perfect condition, without losing quality while thawing? Microwave heating is the worst way for thawing. Microwave-thawed tuna is spoiled by being partly heated or even cooked. How about thawing under running tap water? This is one popular way to thaw frozen food; tuna is covered by a plastic bag and thawed slowly. The problem of thawing by this way is temperature increase of the surface. Temperature of the surface becomes close to tap water during thawing, and enzymatic activities of the raw part of the tuna causes discoloration, off-notes, and unwanted drip. I learned through trial and error, and found the way to thaw tuna in icy water, covering it with a plastic bag. In this way, the surface of tuna remains around 0℃/32℉. At this temperature, tuna is defrosted without generating off-notes and drip, because enzymatic activities are inhibited.

Team TREHA®: We didn’t expect that ice would be used for thawing frozen tuna. Can we use this method for other frozen foods as well?

Prof. Suzuki: Our team applied the same method to other frozen foods. We found this way is suitable for frozen ingredients which are not heated when consumed, such as fish fillets other than tuna, as well as fruits.

Team TREHA®: If the key is keeping the thawing temperature around 0℃/32℉, how about using a refrigerator with a temperature control function?

Prof. Suzuki: Even though the temperature is similar, difference between a refrigerator and icy water is thermal conduction. Water has around 20 times higher thermal transfer (coefficient) efficiency compared to air. Imagine you are in a sauna bath – you can enjoy a sauna bath of 100℃/212℉, but no one can enjoy the hot water bath at the same temperature. Therefore, using icy water is better than using a refrigerator, because in a refrigerator, thawing takes much longer. In terms of time required, quicker is better to maintain quality.

Team TREHA®: How about frozen foods which require heating before consumption?

Prof. Suzuki: In some cases, raw ingredients with active enzymes should not be defrosted before cooking. For example, beef steak does not have to be thawed prior to cooking. By starting pan-frying from a frozen state, we can quickly pass-through the vulnerable temperatures that enzymes become active in. Place frozen steak in a pan and heat it with a lid for 2 to 3 minutes. When you can see the bottom side becoming nicely brown, flip the meat and fry the same way. Turn off the heat, and cook the meat through with the remaining heat on the pan – you can enjoy a perfect medium-rare beef steak. Although cooking method varies among ingredients, thawing is not always necessary.

Concept of “Systematic Freezing” – Quality is determined by multiplication of processes

Team TREHA®: Now we understand that every process of freeze-thaw is important, including pretreatment and thawing.

Prof. Suzuki: We should consider that all the steps together are key to maintaining the quality of frozen food, such as pretreatment, storage condition, and thawing method. I call this concept “systematic freezing”, to produce high quality frozen food by understanding a big picture of frozen food production. I use a mathematical expression to explain;

Frozen Food Quality = 1. Ingredient Quality & Cooking Method × 2. Freezing Method × 3. Storage Condition ×4. Thawing of Cooking Method

Quality of frozen food is multiplication of quality loss, not just an addition. So, if any element is “zero”, quality becomes zero as well.

Team TREHA®: Do you have any words of wisdom for food ingredients suppliers like NAGASE Group?

Prof. Suzuki: Conducting pure research is sometimes difficult for food manufacturers producing commodities for consumers. I believe ingredients suppliers such as Nagase group support the “food science” behind high quality products. We still have unknown mechanisms related to frozen food quality, including the functions of saccharides and proteins – I expect breakthrough achievement through pure research conducted by ingredients suppliers like Nagase.

Team TREHA®: Now we understand frozen food high in quality is the fruit of our efforts, from pure to applied research, and highly considered processes and formulations. Thank you very much for your time.

Did you find this blog interesting?

Please share it with your friends in the food service industry.

We regularly update the blog about the food culture of Japan, where TREHA® was discovered for culinary applications.

Click here and send us a message to subscribe.

Or hit us up on Instagram @trehalose_sensei!